Optiline AI-Powered Cosmetic Grading, Built for Recovery at Scale

Stop replacing components you don't need to replace

Your grading process is burning cash on phantom defects. Internal analysis showed manual operators were replacing up to 20% more cosmetic parts than specifications actually required because human judgment couldn’t consistently apply the standards.

Optiline’s automated cosmetic grading eliminates that invisible overgrading, cutting unnecessary replacements and reclaiming lost yield.

The hidden cost of subjective grading

Manual grading inherently has a costly consistency problem. One operator flags a unit for rework. Another would’ve passed it. Decisions change from shift to shift, hour to hour.

Here’s the best manual grading can realistically deliver:

- 75% max repeatability across operators

- Decisions that drift over time and location

- 20% more cosmetic replacements than specs require

- No visibility into how actual calls compare to intended standards

Operators tend to over-apply cosmetic rules to be safe. But that safety buffer means tossing usable parts and bloating your cosmetic inventory.

OptiLine fixes this. AI-powered defect detection evaluates actual device condition, compares it to what the spec says should pass, and calls it objectively every single time.

Why AI grading outperforms manual inspection

Trained on 20,000+ samples that capture edge cases human training misses

Built using real-world annotated returns and synthetic defect images generated in NVIDIA Omniverse to catch defects operators consistently overlook.

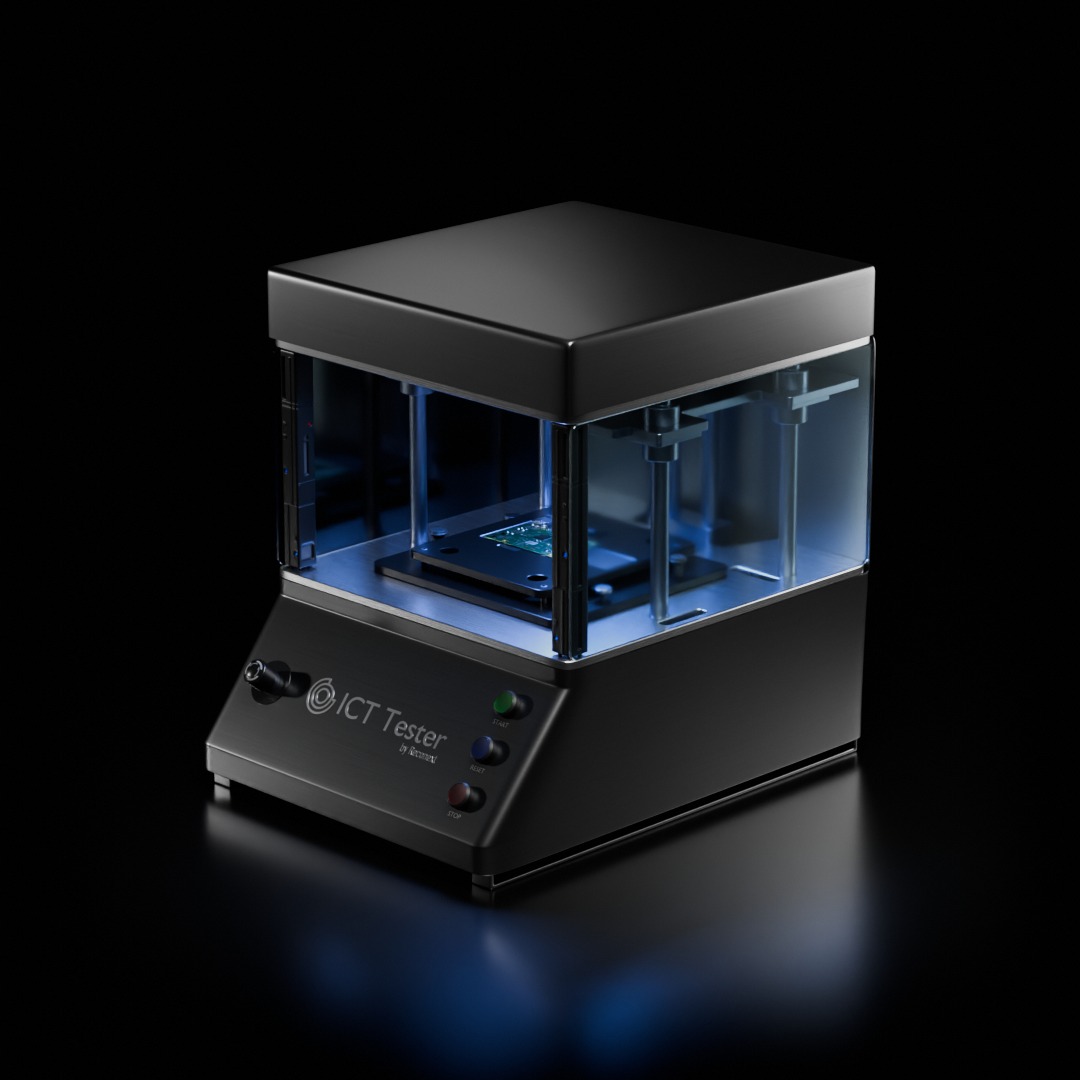

Proprietary lighting reveals defects invisible to standard inspection

Directional control and moving light wave techniques expose subtle blemishes that cause inconsistent human judgment calls.

Flexible grading logic eliminates operator drift

Adjust standards dynamically based on region, customer tier, or product lifecycle stage, delivering the same precision every time.

Automated work instruction cuts rework confusion

Integrates with ERP to direct cosmetic operators: swap top cover only, leave rear intact, etc. No more guessing what needs replacement.

Data Security and Traceability

- Serial-level documentationEvery cosmetic decision recorded with retrievable images for complete audit trails.

- Full traceability integrationERP connectivity ensures automated workflows and real-time tracking.

- Version-controlled standardsGrading specifications mapped to customer requirements with change management.

- Analytics and optimizationGrafana dashboards enable QA teams to validate warranty claims and tune specs.

%

Grading Repeatability

%

Increase in Yield Recovery

Units Processed Daily

Customers Re-calibrate Specs

%

Reduced Cosmetic Stock & Rework

How Optiline Eliminates Grading Guesswork

Clean

01

Grade

02

Route

03

Track

04

Every decision recorded at serial level with retrievable images. Data flows to Reconext ERP for automated workflows and yield analysis via Grafana dashboards.