Repair & Refurbishment

Reconext engineers repair and refurbishment solutions to restore value to used electronic devices.

We extend the lifespan of returned equipment and have the ability to restore devices to like-new condition. In many cases, this enables our customers to avoid new replacement purchases, contributing to the circular economy.

Our repair services begin with fully objective testing and grading to determine the initial condition of the returned device. From there, we apply sophisticated, customized routing rules to determine the optimal level of refurbishment to meet the needs of our customers.

Objective Testing

Reconext utilizes proprietary, automated testing equipment to get standardized, unbiased results.

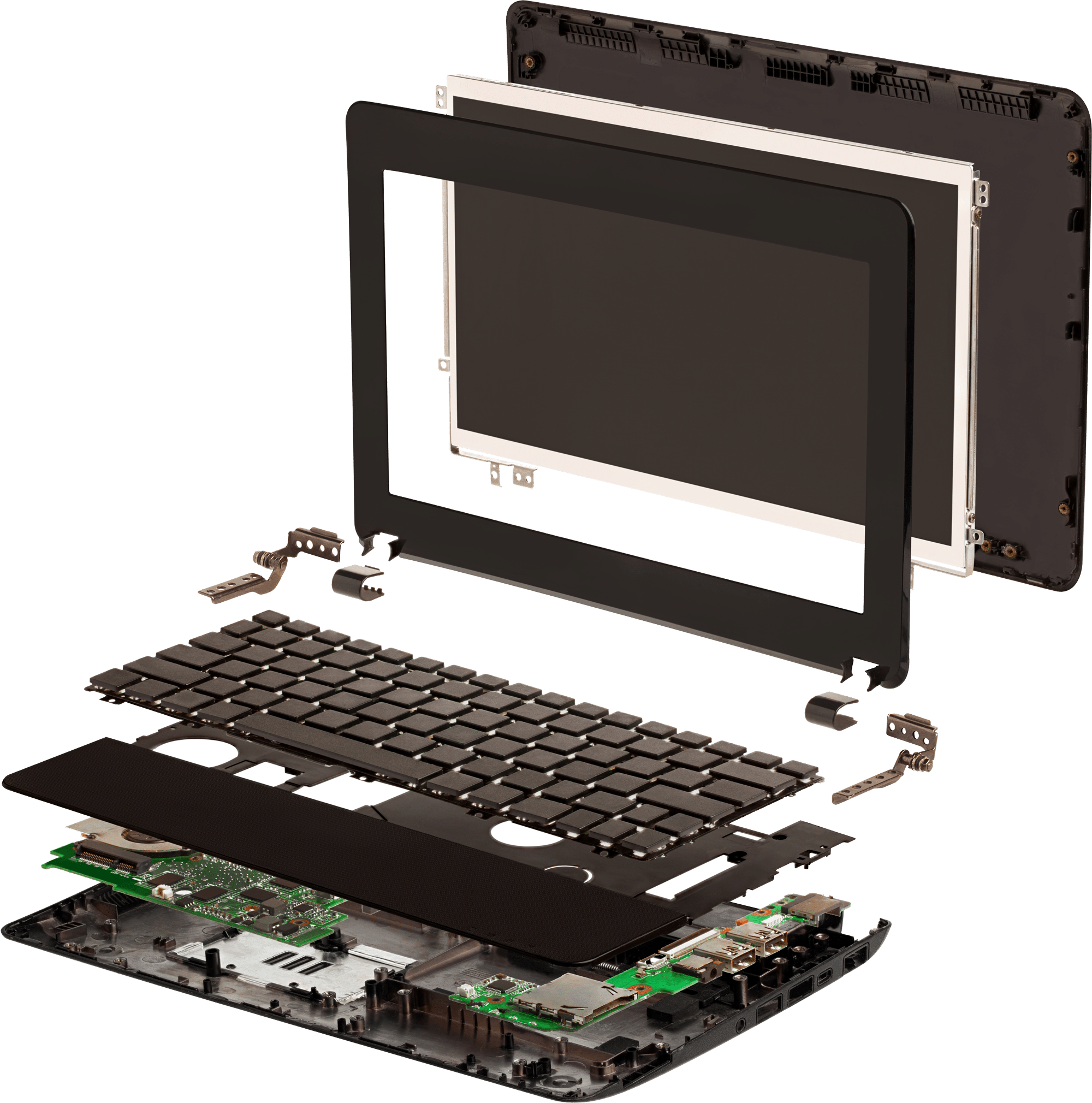

Parts Harvesting

We reclaim functional and cosmetic device parts, such as LCDs, housings, circuit boards, flex cables, Wi-Fi modules, speakers, vibrators, glass, buttons, and midframes, as well as rare earth materials.

Functional Repairs

Over 4,000 trained technicians provide level 1 to level 4 repairs for electronic components. Advanced capabilities include complex ball grid array (BGA) reworks, display and LCD refurbishment, and more.

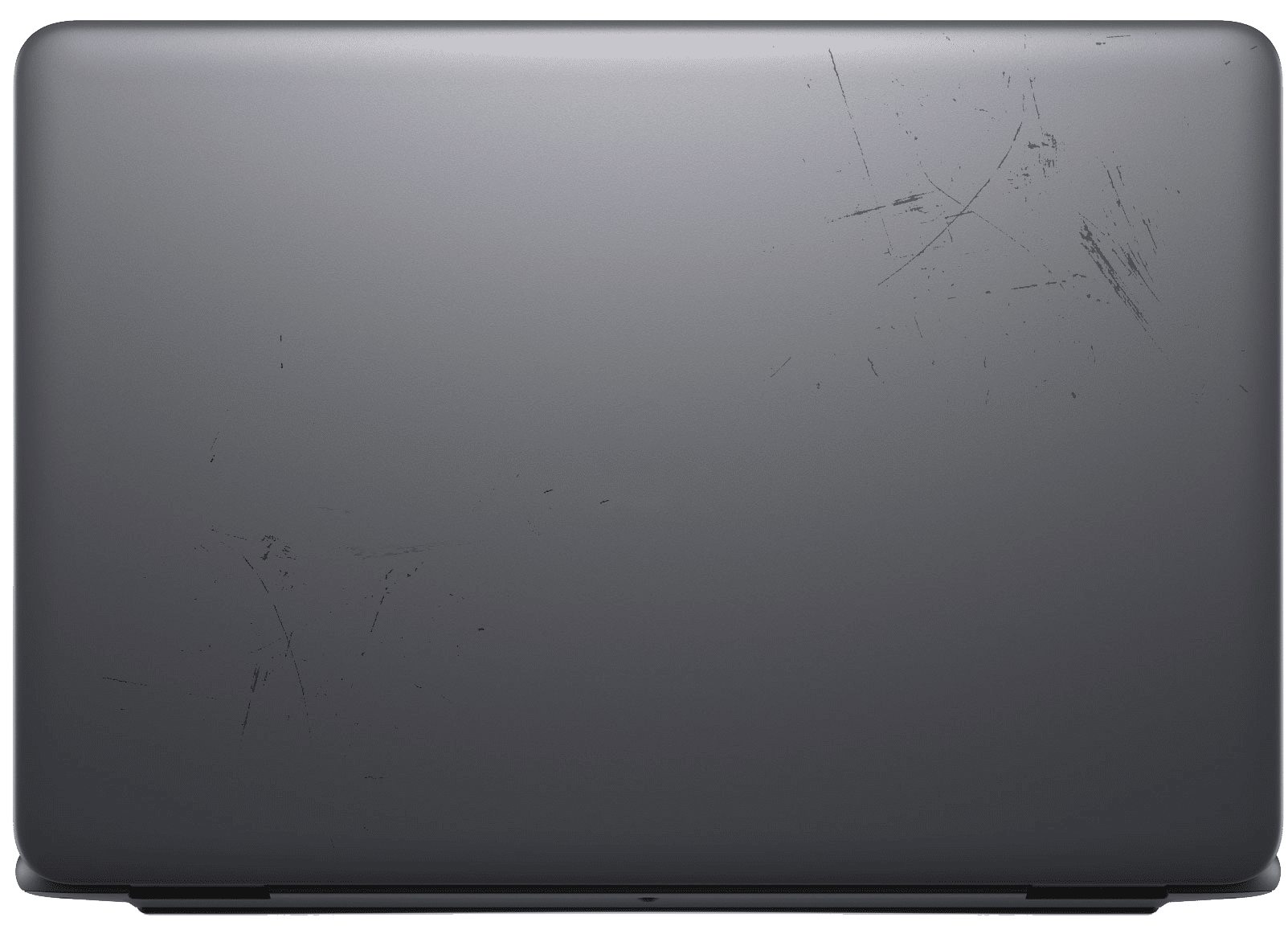

Cosmetic Refurbishment

Reconext offers a full suite of options for metals, plastics and glass to return surfaces to like-new condition.

When Appearance Matters

HYPR: High Yield Parts Reclamation

Our innovative processes allow us to go deeper to reclaim a higher percentage of parts and components. These parts are tested, requalified, and tracked throughout the repair process. Using more reclaimed parts reduces the need for replacement parts (providing cost savings) and increases overall circularity.

Integrating Returns Management with Repair Yields Superior Results

Reconext has the ability to provide a global, standardized returns and repair solution with in-market coverage to minimize transportation costs and transit times. Combining returns management with repair and refurbishment creates significant efficiencies by eliminating unnecessary shipping legs and duplication of touches. Additionally, time-to-market is accelerated allowing a quicker path to internal device redeployment or value recovery.

Global Footprint

We are where you need us. With 17 Service Centers located in key regions across the world, we can offer a truly global solution.

State of the Art Facilities

We have what you need. A full-service provider, we leverage: class 100 clean rooms, burn-in systems, anodizing equipment, automated conveyance, robotic processing lines, and full reliability testing labs.

Engineering

We have the people you need. Employing over 400 engineers company-wide, Reconext develops custom processes and solutions to bring used devices back to like-new condition while maximizing reuse of original parts and components.

Picturing One Global Repair Solution for a Leading Action Camera Manufacturer

Reconext provided a global reverse logistics and refurbishment solution.

Global visibility of all returns in-network

INCREASED

Reduced annual spend on new product buys by

$2.4M

Overall Circularity

INCREASED

Book a call with one of our experts to receive a preliminary assessment of your project